Low Temperature Heat use

- ProductsZeolitic Water Vapor Adsorbent

- Manufacturing companyFahrenheit (Germany)

- Relation

- Adsorption heat pump

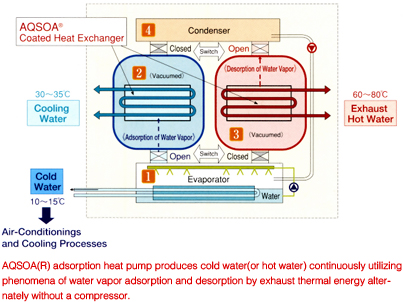

Mechanism of Adsorption Heat Pump

- Save energy for effective utilization of waste heat.

- Be environmentally-friendly, neither CFCs nor HFCs is needed.

- Make little noise and little vibration, because of no need of compressor.

- Be easy for operation and maintenance.

Merits of Adsorption Heat Pump

Evaporation

Sprayed water evaporate on the pipes, in which water flow, in a vacuumed evaporator. And the water in the pipe is cooled by latent heat of evaporation.

Adsorption heat pump produce cold water.

Adsorption

Coated heat exchanger adsorbs vapor from the evaporator.

Desorption

Hot water in the pipes regenerate adsorbent on the heat exchanger. And the vapor transfer to the condenser.

Condensation

Vapor from the coated heat exchanger condenses on the pipes cooled by cooling water. Condensed water flow back to the evaporator.

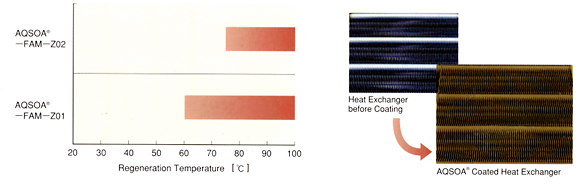

Coated Heat Exchanger for Adsorption Heat Pump

Recommended Regeneration Temperature Range

Typical Dimensions

Performance of FAM-Z02 adsorption heat pump compared

with silica gel adsorption heat pump and absorption heat pump.

Expected Performance Ratio of The Heat Pumps with Decreasing Regeneration Temperature.

100% standard performance is defined that at 88℃ for regeneration, 31℃ for cooling water and 9℃ for producing cold water.